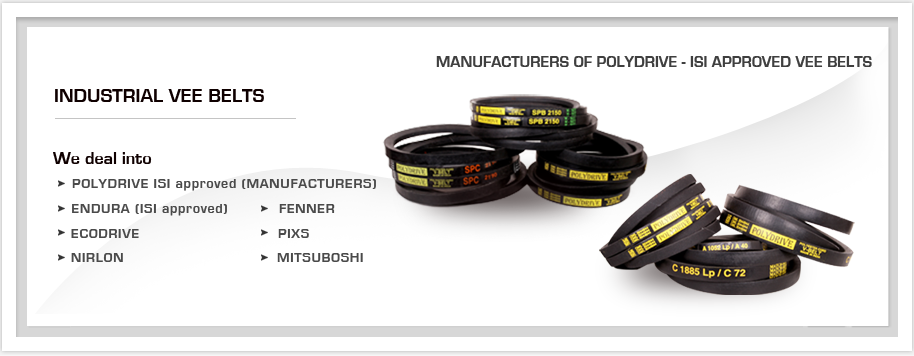

INDUSTRIAL BELTS

Vee Belts

Vee belt is an endless power-transmission belt which are looped over pulleys with a V-shaped groove. It transmits higher torque at less width and tension than a flat belt. It is most commonly known as fan belt. Vee - Belts are the cheapest & most widely used in heavy industries for power transmission between shafts.

Range :

| Section | Nominal Top Width (mm) | Nominal Thickness (mm) | Angle (Deg.) | Size Range (inch) | Pitch Length (mm) |

| A | 13.0 | 8.0 | 40 | 16* - 225* | 36 |

| B | 17.0 | 11.0 | 40 | 19* - 598* | 43 |

| C | 22.0 | 14.0 | 40 | 36* - 598* | 56 |

| D | 32.0 | 19.0 | 40 | 95* - 598* | 79 |

| E | 38.0 | 23.0 | 40 | 100* - 598* | 92 |

Wedge Belt

Wedge Belts are used in demanding drive systems in all spheres of mechanical engineering. High power transmission capacity and economic efficiency coupled with a long service life are the hallmarks of this type of belt. The high quality standards of these products mean they are widely used in industrial and agricultural machinery where they are subject to greater stress. They are especially suitable for drives with high belt speeds. These belts use up to 50% smaller pulley widths than classical sections, allowing more compact drives

Range :

| Section | Dimension | Angle | Pitch Width | Belt Length Factor | Standard | Recommended Min pulley diameter |

Range | |||

| A mm |

B mm |

Deg. | Wp mm |

Lp to La mm |

Li to Lp mm |

Li to La mm |

||||

| SPZ | 10 | 8 | 40 | 8.5 | 13 | 37 | 50 | IS 14261 | 67 | 710-4953 |

| SPA | 13 | 10 | 40 | 11.0 | 18 | 18 | 63 | IS 14261 | 100 | 1320-9144 |

| SPB | 17 | 14 | 40 | 14.0 | 28 | 28 | 88 | IS 14261 | 160 | 1320-13000 |

| SPC | 22 | 18 | 40 | 19.0 | 30 | 30 | 113 | IS 14261 | 224 | 2550-12500 |

Cogged Belt

Rubber cogged belt is the combination of V Belt & Flat Belt. Cogged belt is a type of V – Belt that is notched on its underside to allow the belt to flex more easily. It has not only the soft & tenacious features of flat belt but also has compact & high efficient merits of V Belt. Recommended for tough, small sheaves and high tension drives Cogged belt slips less due to teeth in its inner side.

Range :

| Belt Type | Top Width A (mm) |

Height B (mm) |

Angel q (°) |

Belt Outside Length in inches |

| ZX/X10 | 10.0 | 6.0 | 40 | 20-157 |

| AX/X13 | 13.0 | 8.0 | 40 | 20-157 |

| BX/X17 | 17.0 | 11.0 | 40 | 22-157 |

| CX/X22 | 22.0 | 13.5 | 40 | 30-157 |

| Belt Type | Top Width A (mm) |

Height B (mm) |

Angel q (°) |

Belt Ptch Length in mm |

| XPZ | 9.7 | 6.0 | 40 | 600 to 1900 |

| XPA | 12.7 | 10.0 | 40 | 600 to 4000 |

| XPB | 16.3 | 13.0 | 40 | 600 to 4000 |

| XPC | 22.0 | 17.5 | 40 | 1000 to 4000 |

| X20A | 21.5 | 13.0 | 38 | 650 to 4200 |

| HAX | 13 | 7 | 40 | 650 to 4200 |

| HBX | 17 | 9 | 40 | 650 to 4200 |

| Effective Length in inches | ||||

| 3VX | 9.7 | 8.0 | 40 | 24 to 157 |

| 5VX | 15.8 | 13.5 | 40 | 31.5 to 157 |

Timing Belt

These belts have teeth that fit into a matching toothed pulley. Timing Belts when correctly tensioned maintains constant speed during power transmission, they have no slippage and are often used to transfer direct motion. Timing belts need the least tension of all belts, and are among the most efficient. Timing belt make less noise, has high transmission capacity & efficiency. Replacement of Timing Belts is time & cost saving

Range :

| Range | MXL | XL | L | H | XH | XXH |

| Pitch | 2.032 MM | 5.080 MM | 9.525 MM | 12.70 MM | 22.225 MM | 31.750 MM |

HTD Timing Belts & STD Belts

HTD Belts is high torque drive belts of curvilinear tooth form. It is more compact and more economical belt from Industrial synchronous belts made of international quality standard. STD Belts is referred to SuperTorque drive belts. These special curvilinear tooth design belts are available in wide range and size.

Range :

| RANGE | 2M | 3M | 5M | 8M | 14M | S2M | S3M | S4.5M | S5M | S8M | S14M |

| PITCH | 2.0 MM | 3.0 MM | 5.0 MM | 8.0 MM | 14.0MM | 2.0MM | 3.0MM | 4.5MM | 5.0MM | 8.0MM | 14.0MM |

PU Timing Belt

Polyurethane Timing Belts are manufactured from wear resistant Polyunrithane & high Tensile Steel Cord. Due to the cords, these belts posses greater length stability & capacity to bear load. These are widely appreciated for their high power transmission capacity, resistance to corrosion & abrasion, low noise , low maintenance & high flexibility.

| RANGE | XL | L | H | T2.5 | T5 | T10 | T20 | AT5 | AT10 | AT20 |

| PITCH | 5.08 MM | 9.525 MM | 12.70 MM | 2.5 MM | 5.0 MM | 10.0 MM | 20.0 MM | 5.0 MM | 10.0 MM | 20.0 MM |

Poly Rib Belt

Poly Rib Belts offer several advantages as compared to V Belts, Wedge Belts, Flat belts. Poly Belts are particularly good in terms of smaller pulley diameters, high belt speed & narrow face widths which conventional belts are unable to handle. The Poly belt is gaining wide acceptance in the automotive fields due to advantages it exhibits. Multi-Pull Ribbed belts offer high power capacity in a single flexible low stretch belt. The continuous high tensile synthetic cord makes maximum utilization of the face width and ensures a uniform tension throughout the belt. Some other major benefits of Poly Belts are

- HIGHER POWER

- ZERO SLIPPAGE

- HIGHER BEARING LIFE

- SILENT DRIVE:- vibration and noise free power transmission

- SINGLE BELT:- Eliminates the use of multiple / matched set belts

- LONGER LIFE

- LOW DOWNTIME & REPLACEMENT COST

| pj | pk | pl | pm |

| 2.34mm | 3.56mm | 4.7mm | 9.4mm |

Polyflex Belts

Poly flex belts are also known as wide angel Polyurethane V Belts. Poly flex belts are strong & compact designed belt which has nominal top width between 3 mm & 11 mm. It transmits extra power, allows higher speed & smooth drives with minimum vibration . It is suited for smallest diameter pulleys & compact drives. These belts are superior ozone & weather resistance.

Range :

| 3m | 5m | 7m | 11m |

| 3x2 | 5x3 | 7x5 | 11x7 |